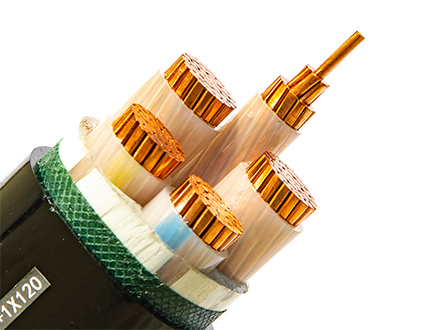

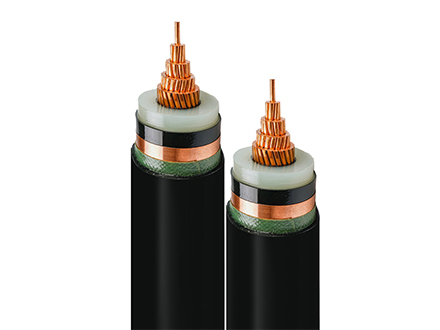

QinFeng's Military-Grade Shielded Cables are engineered for extreme combat environments, combining ultra-resilient materials with signal-integrity technologies. Designed for deployment in aerospace, armored vehicles, and field communications, these cables feature:

Tactical-Grade Construction: Polyurethane jackets resistant to chemicals, abrasion, and cuts.

EMI/RFI Shielding: Triple-layer shielding (foil + braid + drain wire) eliminating interference in high-threat electromagnetic environments.

Hybrid Fiber-Copper Options: OM2 50/125 duplex fiber cores for high-bandwidth data + power conductors.

| Feature | Competitor Standard | QinFeng Advantage |

| Durability | -20°C to +60°C | -40°C to +75°Coperational range |

| Crush/Impact Resistance | 500N/100mm | 1,000N/100mm(EIA/TIA-455-41 military req.) |

| Connector Security | IP65 | IP67-rated stainless steel M12/M23 connectors |

| Signal Integrity | ≤1.5 dB/km loss | ≤0.5 dB/km @ 850nm (OM2 fiber) |

Key Innovations:

Zero-Corrosion Design: 316L stainless steel connectors withstand salt fog/chemical exposure.

Modular Field Repairability: Quick-termination LC/ST/SC connectors enable frontline maintenance.

Custom Configurations: Lengths (0.2m–100m), hybrid wiring (e.g., M23 to D-SUB), mission-specific shielding.

Company Cases & Experience

Armored Vehicle Comms Retrofit

Challenge: Vibration-induced fiber fractures in desert operations.

Solution: Deployed crush-resistant MF95ZZ-reinforced cables with polyurethane jackets.

Outcome: 0% signal dropout during 3-month deployment; 60% lighter than legacy systems.

Why Choose QinFeng?

Military DNA: 10+ years as OEM for PLA/NATO electronic warfare systems.

Vertical Manufacturing: In-house production of fibers, alloys, and connectors—no outsourcing.

Rapid Deployment: 48-hour emergency prototyping + global logistics.

Compliance Mastery: Full-spectrum testing per EIA/TIA-455-25 (impact), EIA/TIA-455-41 (crush), and MIL-T-55181.