+86 186 2902 8721

+86 156 1293 3210

+86 186 2902 8721

+86 156 1293 3210

January 26, 2026

Share:

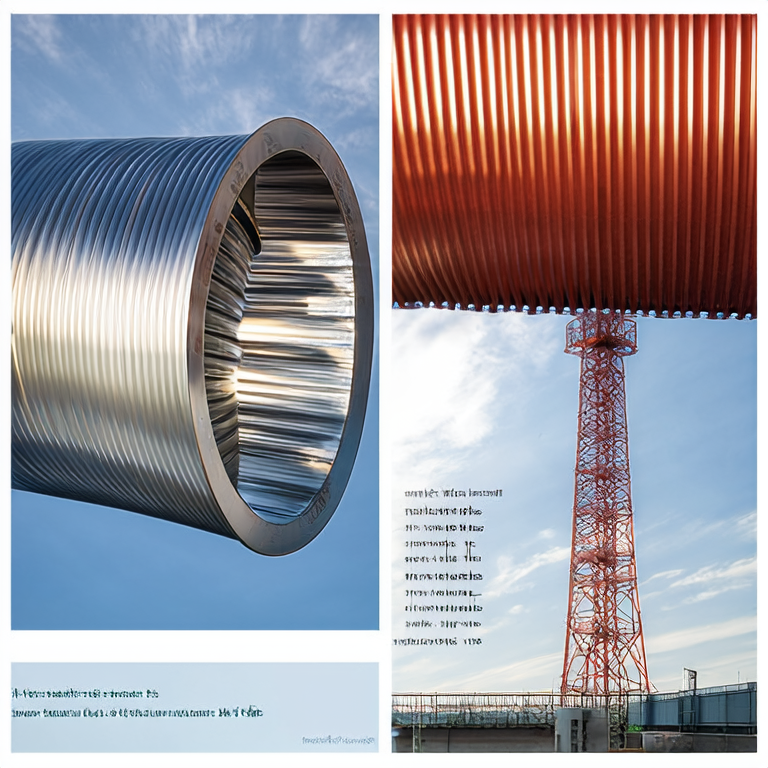

In today’s world, where energy efficiency is becoming increasingly important, the emergence of Aluminum Alloy Power Cables has revolutionized the electrical cable industry. The growing shift towards sustainable and cost-effective electrical solutions has led to a significant increase in the adoption of these cables. Many industries, including construction, renewable energy, and transportation, face challenges related to weight, conductivity, and corrosion. With Aluminum Alloy Conductors, addressing these pain points is no longer a distant possibility. They not only provide substantial benefits compared to traditional copper cables but also play a crucial role in optimizing energy consumption and reducing overall operational costs.

Aluminum Alloy Conductor Power Cable consists of a core made from aluminum alloy, which combines several metal elements to enhance electrical performance and durability. Unlike standard aluminum or copper cables, this innovative design reduces common issues like thermal sagging and improves conductivity. According to IEEE Standards, aluminum alloy conductors can achieve a conductivity of over 61% of copper, making them a viable alternative in various electrical applications.

The industry\'s significance lies in understanding that selecting the right conductor material can lead to improved energy efficiency and significant cost savings during installation and operation. As industries continue to embrace renewable energy sources, understanding the properties and advantages of aluminum alloy conductors becomes indispensable.

Aluminum Alloy Conductor Power Cables find extensive application in numerous fields, including but not limited to:

Renewable Energy: These cables are particularly utilized in solar power plants, where the lightweight characteristics facilitate easier installation and reduced structural support requirements.

Heavy Industries: High-voltage transmission lines in industries such as mining and manufacturing often rely on aluminum alloy conductors for enhanced performance under challenging conditions.

Transportation Infrastructure: Railways and urban transport systems have adopted aluminum alloy cables due to their ability to withstand environmental stressors while maintaining optimal performance.

This wide range of application areas underscores the versatility of aluminum alloy conductors and their crucial role in modern electrical infrastructure.

The benefits of using Aluminum Alloy Power Cables are numerous and can significantly impact project outcomes:

Weight Reduction: Aluminum alloy cables are up to 50% lighter than copper cables, making them easier to install and manage, especially in overhead applications.

Cost Efficiency: Studies show that aluminum conductors can reduce installation costs by approximately 30% due to lower labor and support structure requirements.

Enhanced Conductivity: With an improvement in conductivity ratings, these cables demonstrate less energy loss during transmission. For instance, aluminum alloy conductors can exhibit a loss reduction of around 6% compared to traditional copper cables.

Corrosion Resistance: Aluminum alloys are known for their resistance to oxidation. This property extends the lifespan of the cables, meaning fewer replacements and repairs, leading to significant long-term savings.

Understanding these advantages is important for industry stakeholders looking to make informed decisions on electrical infrastructure.

For those interested in delving deeper into aluminum alloy conductors, it\'s essential to read the user guide provided by manufacturers like Qinfong. This guide offers valuable insights into the installation and maintenance of aluminum alloy power cables, ensuring optimal performance and safety.

Q: How does aluminum alloy compare to copper in terms of electrical conductivity?

A: Aluminum alloy conductors boast a conductivity rating of about 61% compared to copper, which is at 100%. However, their lightweight and corrosion-resistant properties make them an attractive alternative in various applications.

Q: Can aluminum alloy cables be used in high-temperature environments?

A: Yes, aluminum alloy cables are designed to withstand elevated temperatures while maintaining integrity and performance, which is essential for industries operating under demanding conditions.

Q: What are the installation cost benefits of using aluminum alloy cables?

A: Utilizing aluminum alloy cables can lead to installation cost reductions of up to 30%, primarily due to lower labor costs and lighter cable weights, resulting in less structural support needed.

The transition to Aluminum Alloy Conductor Power Cables represents a significant technological advancement in the electrical cable industry. With their numerous benefits, including weight reduction, cost efficiency, and enhanced conductivity, they are becoming a necessity rather than a choice. Brands like Qinfong are paving the way for broader adoption of this technology, helping industries transition sustainably and efficiently.

For anyone seeking to understand the full potential of aluminum alloy cables, trial usage or consultations with professionals in the field can yield valuable insights and practical experience.

Rencent News

Can aluminum alloy cable replace copper cable directly?

January 28, 2026

Why choose aluminum alloy instead of copper?

January 26, 2026

How does low voltage wire work?

January 23, 2026

Contact Us

Related Products

General Purpose Rubber Sheathed Flexible Cable

Voltage level: 0.3/0.5KV 0.45/0.75KV

Model: YQ YZ YC YH JHS...

Customization

Our team is composed of experienced experts who are eager to help you find the right solution for your business.

Please specify product categories and specifications

Annual output of customized products: 8000 tons/year

Please specify the voltage: 0.3-35KV

Produce as per CE, UL, RoHS, IEC, etc.

Produce as per customers’ samples